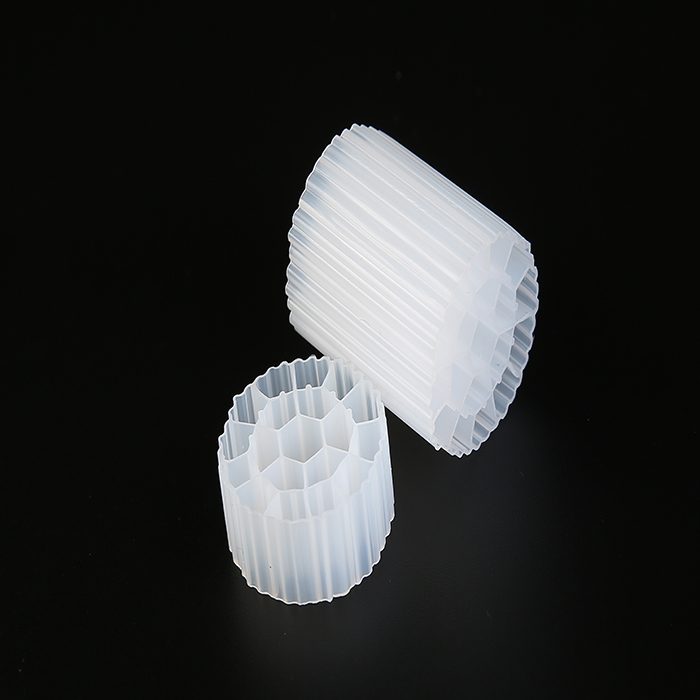

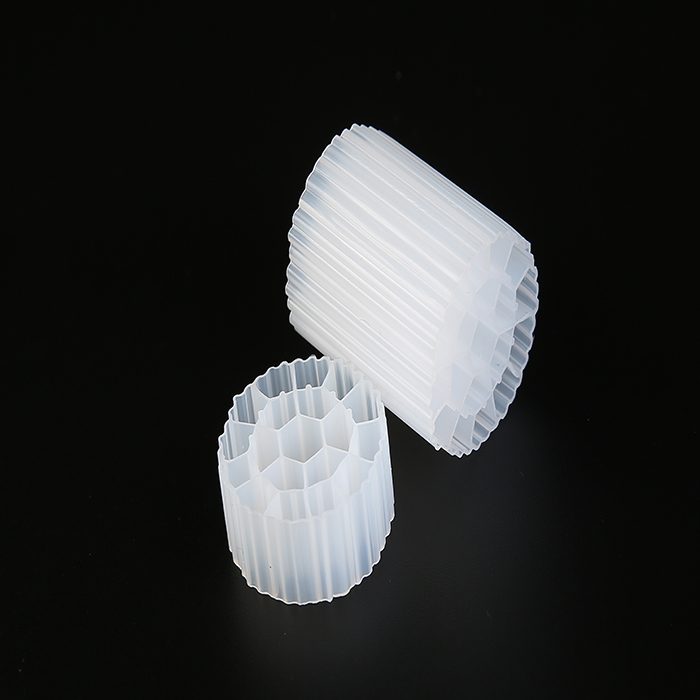

Lower Energy Consumption MBBR Bio Media K2 PE07 MBBR Bio Balls

MBBR Technology and Biofilm Carries

MBBR technology is based on the biofilm principle with an active

biofilm growing on small specially designed plastic carriers that

are kept suspended in the reactor. The technology utilizes the

advantages of both activated sludge and other biofilm systems (e.g.

biofilters, biorotors etc.) without being restrained by their

disadvantages.

The carriers are designed to provide a large protected surface area

for the biofilm and optimal conditions for the bacteria culture

when the carriers are suspended in water.

Solutions based on MBBR technology is mainly used in the following

applications:

+ For new plants, especially those requiring a small footprint and

easy operation, for BOD/COD and nitrogen removal

+ As a high loading system in front of existing biological

treatment - roughing reactor

+ To increase the amount of nitrifying bacteria in existing

activated sludge system using the WOCK OLIVER carrier in a hybrid

plant to meet ammonia limits

+ To implement post-treatment to existing plants for process

improvements

MBBR Technology

Technical Details

The aerated MBBR uses, as the activated sludge process, the whole

volume of an open tank. It is defined as a biofilm system, as the

biomass is growing on carriers that move freely within the reactor

volume and are kept within the reactors by a sieve at the reactor

outlet. The system can be used either for aerobic or anoxic

processes. In aerobic processes the biofilm carriers are kept in

suspension by the agitation created by air from aeration diffusers,

while in anoxic processes a mixer keep the carriers in movement. A

schematic of the principle in an implementation of the WOCK OLIVER

MBBR technology is shown below

| Model | Size(mm) | Specific Surface Area(m2/m3) | Bio-film formation Duration

(days) | Nitrification Efficiency | Preferential Temperature (ºC) | Services life(years) | Number of unites per m3 | | PE05 | Φ25×10 | >600 | 5-15 | 400-1200 | <65 | ≥15 | >118,000 |

|

Small Boss MBBR Filter Media Advantage

Rapid carrier bio film formation mechanism

Super decarburization, ammonia nitrogen removal capacity

Excellent resistance to shock load performance

Flexible way of engineering application

Simple operation and maintenance

Long service life-100% virgin HDPE material.